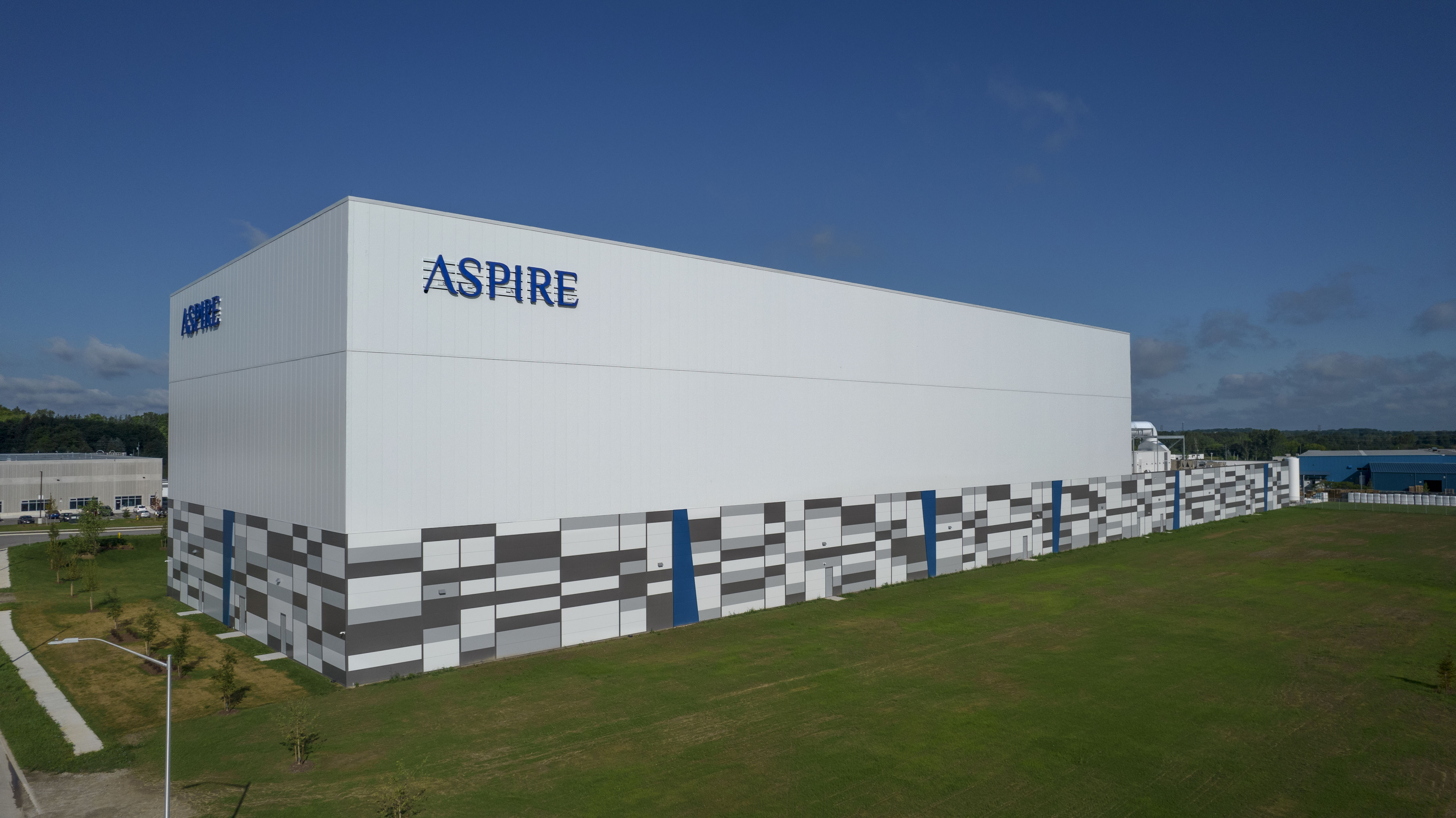

Building the World’s Largest Cricket Farm

Insulated metal panels help keep temperatures constant at $50 million state-of-the-art cricket farm

View Case Studies

Insulated metal panels are pioneering the future of indoor agriculture.

Recently opened in Canada, Aspire Food Group has built the largest indoor cricket farm in the world, utilizing Kingspan's KS Series interior and exterior panels for thermal efficiency and fast install time.

Founded by graduate students from McGill University in Quebec, the Aspire team won the 2013 Hult Prize for social entrepreneurship, securing 1mm in funding for the venture which eventually became Aspire Food Group. The goal of Aspire Foods is to “pioneer sustainable insect agriculture for the good of all” and focuses on creating protein sources that utilize less space and natural resources than traditional farming methods.

IMPs for big aspirations

Kingspan supplied the insulated metal panels for Aspire's first large-scale facility

The high-tech cricket farm requires constant temperatures for insect breeding and storage, which makes this facility a prime candidate to benefit from insulated metal panels, which were manufactured by Kingspan and installed by Thermo Design Insulation (TDI). In addition to keeping crickets at the optimal temperature, the facility includes a frozen goods storage area. KS Shadowline Interior panels have a double tongue and groove interlocking joint, ensuring low thermal bridging.

High R-values on the inside

Kingspan's line of cold storage panels deliver efficient results

Kingspan’s KS Shadowline Interior panels deliver the some of the highest R-values on the market, and are specifically engineered for controlled environments. In addition to their thermal performance, insulated metal panels are also a great fit for facilities that want an eye-catching exterior look to match their high-tech interiors.

The Optimo panels used for the Aspire Food facility integrate seamlessly with the KS Shadowline panel joints, providing an airtightness necessary to ensure a steady temperature and a flawless transition between different areas of the processing center. This also allowed the builder to create colorful accents in the exterior design that makes the Aspire facility stand out among the London landscape.

LOCATION

London, Canada

BUILDING OWNER

Aspire Food Group

CONTRACTOR

EllisDon

MANUFACTURER

Kingspan Insulated Panels

SIZE

165,000 sq. ft.

DATE COMPLETED

2022