Metal Jazzes Up Music Conservatory

Bertram and Judith Kohl Building, Oberlin College Conservatory of Music, Oberlin, OH

View Case Studies

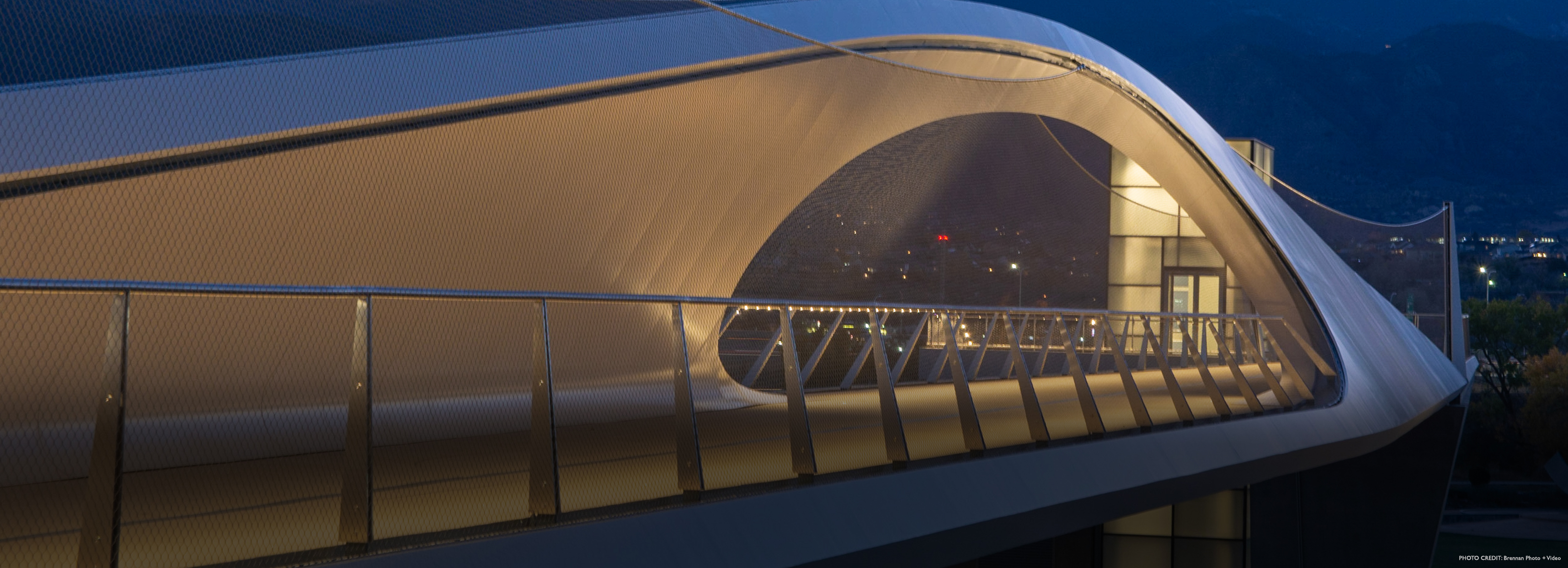

The musical theme and sustainable design of the Bertram and Judith Kohl Building is exemplified by the exterior’s aluminum, which changes color and highlights a variety of shapes as the light shifts. It is the new home for the popular Jazz Studies Program at the Oberlin College Conservatory of Music in Oberlin, OH.

According to Jonathan Kurtz, associate principal and project designer of Westlake Reed Leskosky of Cleveland, OH, aluminum was selected for several reasons—some sentimental and some aesthetic—but especially for the ability to fit unlimited design options. Westlake Reed Leskosky was the engineer, designer, and architect on the project.

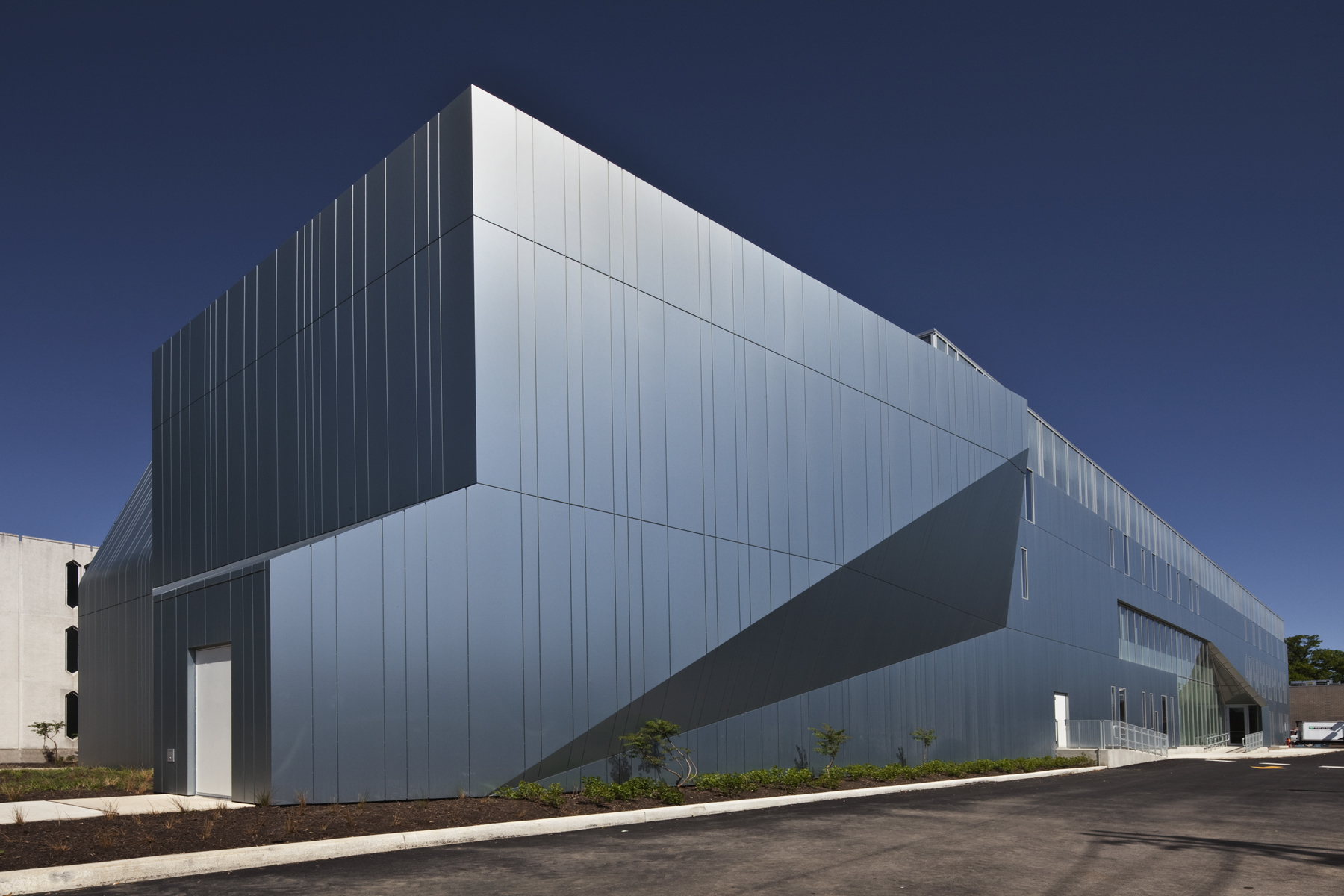

“Our ideal was to use a material we would be able to manipulate to respond to the volumes we created in the building. Metal has a lot of flexibility and that is appealing. We also wanted to create a relationship with nature. The building’s upper level has a lot of windows that become a design element, so we combined metal and glass that at certain times of the day seem to meld with the sky. We also wanted the building to appear a bit less heavy on the site and metal helped do that. If you pictured the same building mass in wood or concrete, it would have a completely different feel,” Kurtz said.

The Kohl Building’s aluminum exterior encloses building elements and is patterned with openings created by cutting and peeling away the metal shell. The windows on the eastern wall appear to dance across the façade with shapes and sizes that correspond to the windows on nearby campus structures.

The metal’s color and finish also tie the new building to parts of the campus designed in the 1960s by architect Minoru Yamaski. “The existing buildings use a precast concrete with an aggregate in it that changes color by day and night. We wanted an unpainted, natural material with a dynamic quality that would allow it to change visually under different conditions. We also wanted to use a similar idea of panels applied to the face of a building, but in a contemporary way, which is why we chose metal,” Kurtz adds.

To achieve these dynamics, a custom finish was designed for the aluminum that allows it to transform in appearance with different light levels. Kurtz’s team chose the Riverside Group of Windsor, ON, Canada, to help determine the type and finish of metal to meet the project objectives.

“We worked with Riverside on another project and knew they did amazing work and would make the final product as precise as we wanted it. Part of our choice for metal is that we knew we had a fabricator who could manipulate the material the way we needed it,” Kurtz notes.

Riverside surveyed the site to determine substrates of the building and created a 3-D model that was used to help custom design each piece to fit the actual built conditions.

“We do that for buildings with complex geometry. It’s not a norm in the industry, but we do a lot of it because of the unique nature of many of our projects. On this one, a lot of credit goes to the architect for a great job of joint patterning and overall design. It gave the building a great look. The design also showed the freedom that metal provides for forming panels and modules into unusual and custom shapes,” notes John McArthur, Preconstruction Services for Riverside.

From the 3-D model, Riverside fabricated and installed 25,000 sq. ft. of aluminum composite material for the exterior walls and 3,000 sq. ft. for soffits. The walls have a custom preweathered zinc finish over brushed aluminum; the soffits have an anodic clear finish.

Krill Construction of Cleveland, OH, was the general contractor for the project.

Aluminum also was a sentimental choice since Oberlin sits above one of the largest deposits of bauxite ore in the country. It was here in 1886 that Oberlin College alumnus Charles Martin Hall developed the cost-efficient process for obtaining aluminum from aluminum oxide that put aluminum into widespread use. Hall became a benefactor to his alma mater and generously donated the Tappan Square property on which the Kohl Building stands.

The Kohl Building also has been awarded the U.S. Green Building Council (USGBC) LEED Gold Certification, making it the first music facility in the United States to reach this level. Several sustainable features were incorporated into the design to achieve this, including a pressure-equalized rainscreen system, geothermal heating and cooling with radiant panels, energy efficient systems and lighting, a green roof system, storm water run-off collection and filtration, sustainably harvested materials, and materials with recycled content such as the aluminum.

The $24 million, three-story, 37,000-sq.-ft. Kohl Building opened in May 2010. It houses a world-class recording studio, flexible rehearsal and performance spaces, teaching studios, practice rooms, a glass-enclosed social hub, an archive of the largest Jazz recording collection in the United States, and collections of rare instruments and jazz photographs from the 1950s.

ARCHITECT

Westlake Reed Leskosky, Cleveland, OH

METAL FABRICATOR AND INSTALLER

Riverside Group, Windsor, ON, Canada

GENERAL CONTRACTOR

Krill Construction, Cleveland, OH

OWNER

Oberlin College, Oberlin, OH

CURVING VENDOR

Curveline, Inc., Ontario, CA

COMPLETED

September 2009

SUSTAINABLE ELEMENTS

- Geothermal heating and cooling with radiant panels

- Energy-efficient systems and lighting

- Vegetative roof system

- Storm water run-off collection and filtration

- Materials with recycled content

- Sustainably harvested materials

- Designed to achieve a level of energy performance 40% better than an ASHRAE 90.1 baseline