Machine Shop Reduces Energy Consumption while Improving Air Quality

Cigas Machine Shop - Pottstown, PA

View Case Studies

Situation

Cigas Machine Shop needs to expand its operations. Owner Craig Cigas finds a vacant 74,000-square-foot building in Pottstown, PA. A strong steel structure and thick concrete slab are positive attributes, but the uninsulated space with 65-foot-high interior volume creates significant operational inefficiencies. The building also has extreme temperature shifts. Using historical data, Cigas estimates the cost to heat the Pottstown machine shop would be roughly $350,000 per year.

Task

Cigas wants to harmonize the heavy industrial shed with a quality workplace that results in reduced energy consumption while offering Cigas Machine Shop employees better air quality. By doing so, the manufacturing operation moves to the forefront of green industrial facilities. AP3C Architects of Philadelphia is hired to design the sustainable renovation.

Action

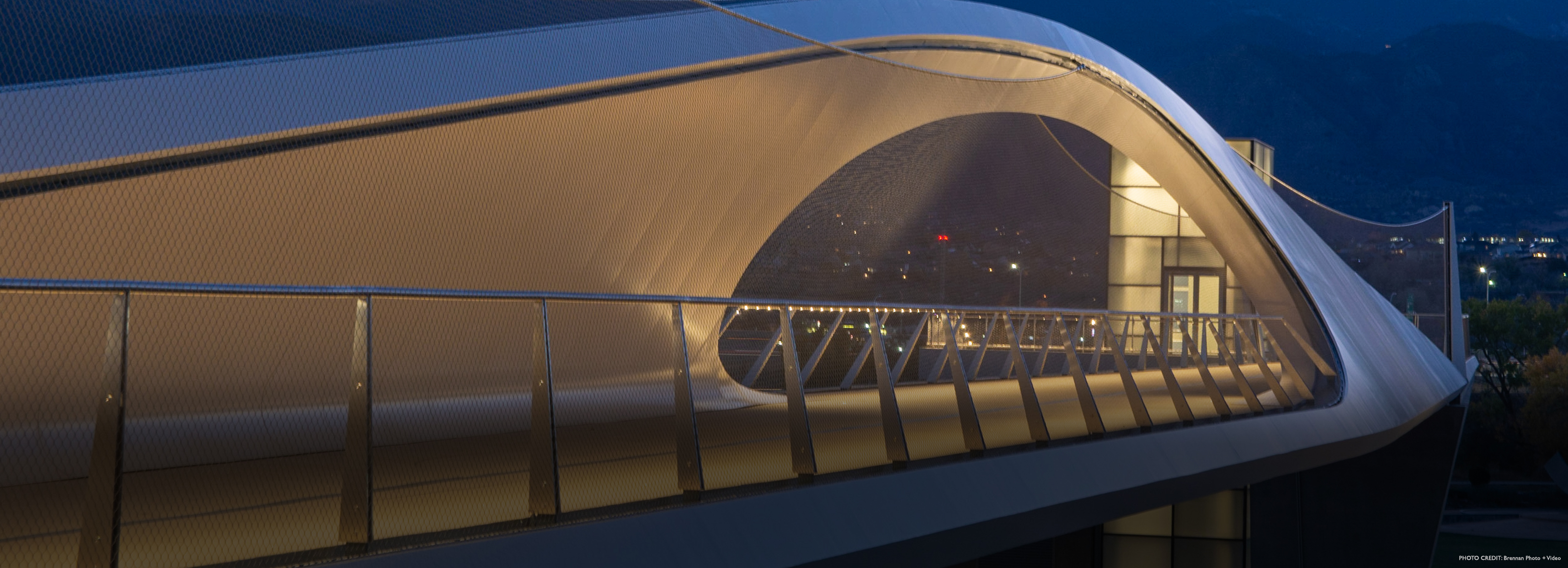

Cigas and his design team layout a new environmentally sensitive footprint along with solar collecting wall panels. The southern façade is covered with a transpired, or porous, solar collector wall system (InSpire Wall) composed of 11,670 square feet of 0.032-inch aluminum wall panels with a black finish.

Results

Actual fuel costs are reduced to just $890 in the first year. “We turned a six-figure problem into a three-figure solution”, Cigas says. “There are a lot of great high- and low-tech solutions in the market, but the key is good design that works with what you can’t change.” Martin Breen of AP3C says the renovation hit the mark. “The machine shop has a contemporary aesthetic that represents the world-class manufacturing processes taking place inside. It stands out in the stark industrial landscape and is a shining example of how industrial facilities can be environmentally responsible."

LOCATION

Pottstown, PA

BUILDING OWNER

Craig Cigas

MANUFACTURER

ATAS International Inc

SIZE

11,670 S.F.