A Powerful Winner

Nebraska Public Power District Norfolk Operations Center, Norfolk, NE

View Case Studies

It’s big, educational, and creative in ways made possible only by metal.

The project is the Nebraska Public Power District (NPPD) Norfolk Operations Center. The 83,000-sq-ft structure consolidates functions previously handled at four separate locations. Completed in September 2010, the highly sustainable facility sets a great example of how a major public utility company can use revenue efficiently while incorporating practices that protect the environment. The building’s sustainable attributes helped it achieve Gold certification in the U.S. Green Building Council’s LEED program.

The sophisticated design with colors and finishes that evoke an energy-based theme attracts attention from near and far. Local groups are drawn to its uniqueness and educational value. Travelers exiting nearby Highway 275 are intrigued by the structure’s brilliance and its expanse of wind turbines and photovoltaic cells. The design also received national attention when it was honored by the Metal Construction Association as the 2011 Chairman’s Award winner for design excellence in a municipal project.

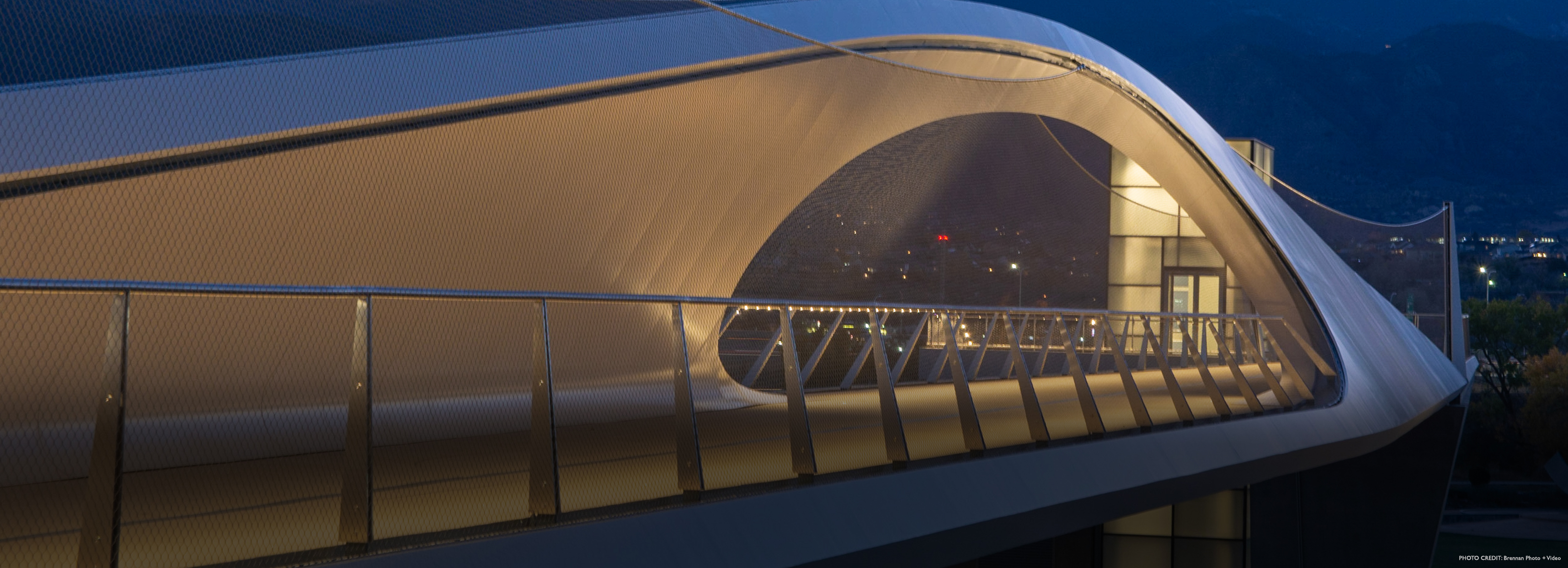

The goal of the design by HDR, Inc., an architecture and engineering firm, was to highlight the simplest elements of electricity and supply the center’s power in an efficient and ecologically sound way. HDR’s Omaha office was the architect of record for the project and David Thomas was the design architect. He decided to use a copper clerestory that rises and curves away from charcoal zinc walls to carry out the image of electrical wire within an insulating black sheath. For this design, he knew metal was the best choice.

“Metal provides long-term durability along with a great appearance that helps represent elements of the facility’s purpose. I use metal whenever I can and it was perfect for this design concept and the high-tech elements of the building. When I think of power and electricity, I think of the old black covering on copper wire, so I chose a black building with copper accents. Metal is the only material that could make that work. We used zinc panels to represent the black and aluminum with copper-colored coating for the copper. The facility manager for NPPD was thrilled that we used zinc and aluminum because he knows they are maintenance free and last a long time,” Thomas said.

4-mm ALUCOBOND® PE Exterior cladding of the contemporary structure is a dry-joint, pressureequalized rainscreen system that incorporates VM Zinc’s Anthra Zinc material from Umicore Building Products USA, Inc., Raleigh, NC. Metal was also used to cover the roof of the main lobby, which has a standing seam metal roof from CENTRIA, Moon Township, PA.

NPPD’s Norfolk Operations Center houses working crews, materials storage, and a customer service center. It also features public exhibits that describe the technologies and efficiency strategies incorporated into the building and its surroundings, including wind turbines, photovoltaic panels, natural landscaping, and water retention techniques.

“We wanted recycled and cradle-to-grave materials so that’s a big reason for using aluminum and zinc and metal in general. The client wanted to go for the LEED Gold certification and that made it a great project to work on. We wanted to showcase how this public utility company practices sustainability and cares for the environment. The educational center where students and residents can come to learn helps do that,” Thomas added.

From a distance, the most visible sustainable aspects are the solar panels and wind-powered turbines. “The solar and wind elements of the project provide a dramatic demonstration of the realities and benefits of renewable power. We put in a rotating photovoltaic system—the largest in the United States at 35 ft high and 70 ft across. It sits on tracks so it can rotate to follow the sun during the day. The computerized system rotates itself back at night. The system is set on a 17-acre site where we restored the native natural prairie. The solar panels are in the middle of the prairie with pathways to allow visitors to see the system. We also used residential wind turbines to show what homeowners can do. The sizes of ours are 25 ft, 30 ft, and 50 ft high, and for homeowners these systems can cost from $12,000 to $20,000. The turbines are wired into the building so kids can sit inside and watch how they work,” Thomas noted.

The solar- and wind-powered systems are connected to computers in the educational center that show in real time how much power is being generated and used. The learning area is housed in a modern lobby that features copper metal column covers and perforated copper “clouds,” which Thomas used to represent electrical power surging across the rolling sand hills of Nebraska.

The building incorporates other real-world sustainable features that are estimated to reduce energy use by 35% annually and have resulted in the LEED Gold certification. The recycled content and long-term durability of the metal panels, which can also be recycled and continuously reused, helped earn points toward this certification.

Operating systems also use low energy. Geothermal heat pumps provide heat through the building, and the garages have radiant floor heat, which Thomas notes is the most efficient heating method for this type of operation. Daylighting techniques are used throughout the building and activity monitors are used to automatically turn lights on and off based on area occupancy.

Another green aspect is native landscaping that saves water and eliminates irrigation. All the rainwater on the property flows into a retention pond, which also hosts native species. These features and the use of low-maintenance metal help reduce operating needs and costs.

“I knew metal would be right for this project and the facility manager was very receptive to it. I like metal because you can get any color and texture you want and create any pattern depending on where you put reveals. We frequently use metal as an addition to a masonry building to give it a whole new look. Metal also creates a focal point when you use a nice colored panel. On a roof, metal is outstanding. There is no better roof than a metal roof. On this building we get a lot of positive comments from residents and visitors. Architecturally a lot of people like it, plus metal is a good alternative cost wise and so much more versatile than masonry,” Thomas says.

From its high level of visibility to its technical functions, the NPPD Norfolk Operations Center draws attention to sustainability and the value of sustainable metal in generating creativity.

LOCATION

Nebraska Public Power District

Norfolk Operations Center

BUILDING OWNER

Nebraska Public Power District

PRODUCTS

VM Zinc Anthra Zinc material from Umicore Building Products USA, Inc., Raleigh, NC; standing seam metal roof from CENTRIA, Moon Township, PA

ARCHITECT

HDR, Inc., Omaha, NE

CONTRACTOR

JE Dunn Construction Co., Omaha, NE

METAL INSTALLER

SGH, Inc., Omaha, NE

PHOTOGRAPHY

Tom Kessler Photography

COMPLETION DATE

September 2010