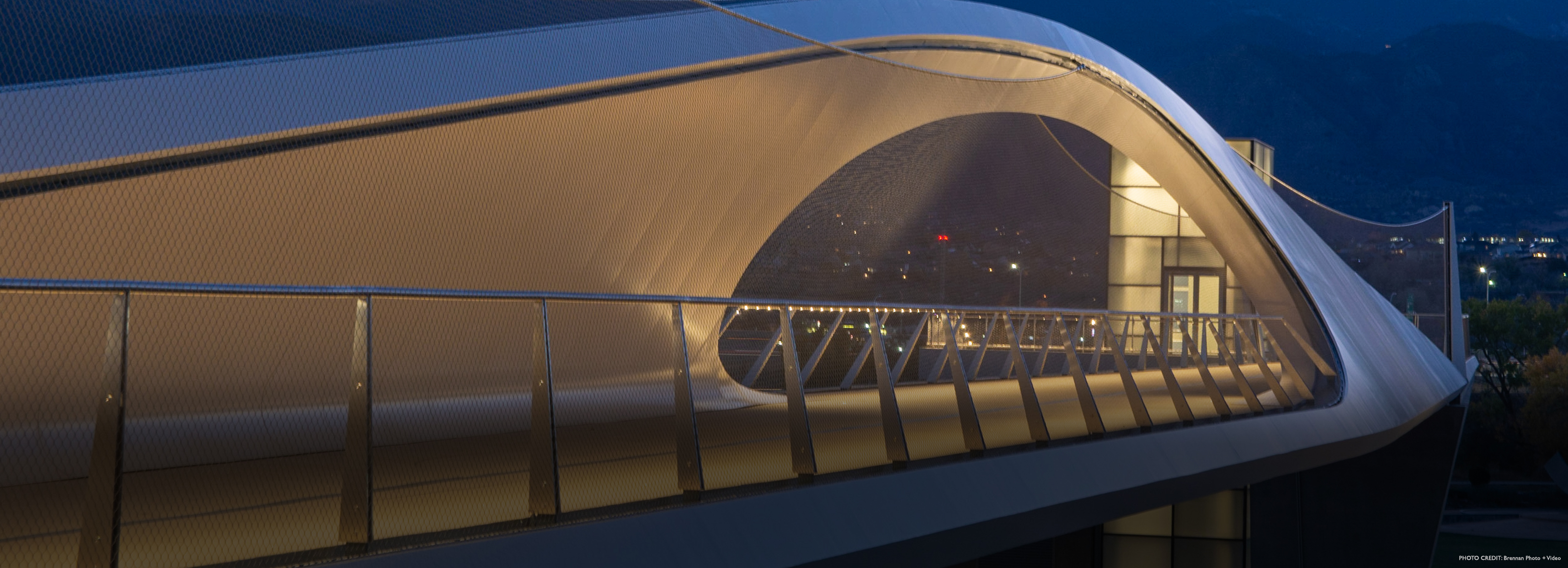

Red Rocks Amphitheatre, Morrison, CO

View Case Studies

The Project

Just west of Denver, nestled among huge red sandstone monoliths in the foothills of the Rocky Mountains at an elevation of 6,450 feet, is the state’s most celebrated piece of architecture.

In 1928, the City of Denver acquired land in the Red Rocks area, formerly promoted as a community park and performance venue with a simple stage and existing rough slope used for seating. Through the joint efforts of many federal agencies and Denver area organizations, an amphitheater was constructed between 1935 and 1941 to provide a more functional concert setting.

The project initially required the removal of 25,000 cubic yards of rock and dirt and used 90,000 square feet of flagstone, 10 carloads of cement, 800 tons of quarried stone and 30,000 pounds of reinforced steel. Known as the only naturally occurring, acoustically perfect amphitheater in the world, Red Rocks has attracted some of the world’s most notable performers, from the legendary “C/W Outlaws,” Sting and The Beatles to opera stars and U2.

Many improvements to the venue have been made over the years. In 2021, the City was looking to expand and upgrade the venue with a larger roofing structure over the main performance stage. An 8,500 square foot Nordic Brown Copper standing seam metal roof was installed to replace the original one. The roof’s high-end copper was shipped from German supplier, Aurubis in coils and fabricated on site. Mounted to the venue’s stunning new roof is the complete DualGard™ snow retention system by S-5!

The Challenge

The new roof sits between 75 and 100 feet above the stage floor. Without a snow retention system, snowpack and ice could easily escape endangering performers, concertgoers and expensive equipment.

Due to the high elevation of the site, extreme weather conditions ranged from freezing rain and snow to warm, dry, and sunny, then back to winter-like conditions throughout the duration of the project. Such weather conditions would also be a concern for the venue once construction was complete and business as usual resumed, therefore a high-quality, long-lasting snow retention system was necessary to prevent melting snow and ice from sliding off the sloped metal roof.

The terrain and mountainous setting of the venue, with long lines of stairs and curvy rocks, presented its own set of challenges. Construction staging areas were limited, and it was difficult to maneuver equipment and material. A crane was required to hoist roofing materials over a wall and around the mountain.

Furthermore, the venue is a designated historical site, requiring a tested, trusted and engineered solution that was aesthetically pleasing and would meet the architectural requirements and specifications for the project.

The Solution

Because the roof is subject to both the downward and upward forces of snow and wind, it required a snow retention system designed to resist stresses in two directions. The DualGard snow retention system by S-5! was custom-engineered for the standing seam roof profile.

Custom powder-coated to match the roof, DualGard is a complete, two-pipe aluminum, snow guard system with strength, testing and quality for almost any standing seam profile so the team was able to accomplish perfect color matching to the copper roof—meeting the architectural requirements for this historical site.

Additionally, the DualGard was easy to transport to such a challenging setting. It is compact and comes in packaging lengths and weights that are 100% UPS-able and easy to handle on site.

LOCATION

Morrisson, CO, USA

CONTRACTOR

GH Phipps, Superior Roofing, Inc.

MANUFACTURER

S-5!

SIZE

8500 square feet