Cutting-Edge Hospital Gets Cutting-Edge Design Treatment

View Case Studies

In order to increase capacity to meet the needs of the growing community and region, the state-of-the-art University Health System's Womenʼs and Childrenʼs Hospital in San Antonio now features a 14-story, 697,000 SF tower and podium to accommodate around 300 patient beds, a dedicated pediatric emergency department, private NICU, and womenʼs urgent care center.

The hospital design was not meant to feel feminine but instead wanted to focus on family-centered care, mirroring the beauty of the surrounding area, and showcase cutting-edge initiatives. With that in mind, a plan was created with evidence-based design principles including care given to provide natural light, expansive views of nature, private patient rooms, and ample space for families.

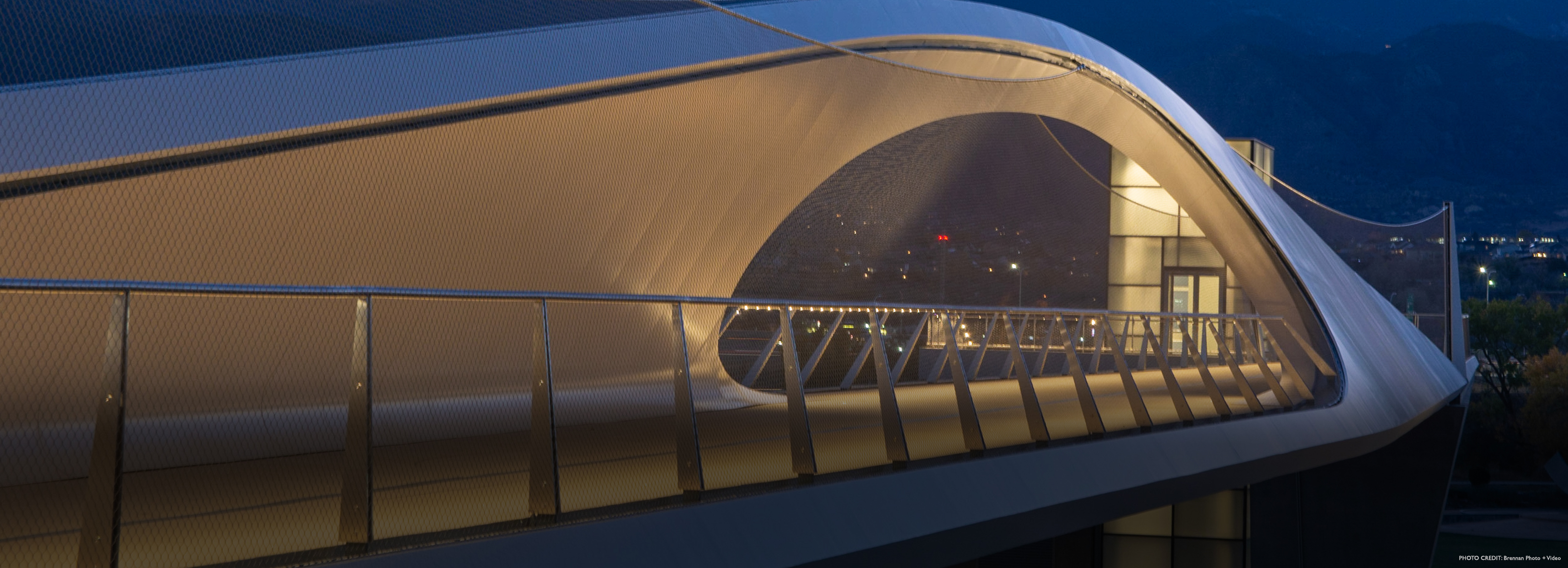

A key part of the project is the 400,000 SF parking garage covered in a combination of over 31,000 SF of Cambridge Magothy Mesh and 106,000 SF of custom aluminum composite that connects directly to the building with the ability to accommodate 900 vehicles. The project involved a strategically-designed, curved east elevation which required precision-engineered segmented aluminum composite panels across multiple elevations.

The strategic positioning of the building, created with LEED certification in mind, aimed at moderating solar heat gain and glare during Texas summers, guided KSC in designing a curved east elevation. This design features segmented aluminum composite panels and louvers, demanding precision in measurements and fabrication to uphold uniform joints along the building's 400-foot curvature. To bring this intricate design to life, three distinct ACM coil finishes were manufactured, all featuring the specified Arcadia Silver finish. To meet the architect's panel size requirements, KSC undertook the production of a single and double-sided EURO Coil finish, which was imported from Germany. Simultaneously, a US coil was produced to cater to isolated project areas and those where the installation transitioned between prefab and conventional methods. Coordinating these different coils became a significant challenge, as their finishes were intended to be identical. However, due to batching capabilities, a visible distinction emerged among the three coils. It was crucial to prevent misplacement, as installing the wrong coil in a specific area would require refabrication. This coordination effort was pivotal to maintaining a consistent finish throughout the project.

To further enhance the project's visual cohesion, continuous ACM joint alignment across multiple elevations (North -> West -> South) were imperative. Meticulous measurements and installation, especially where joints aligned with windows, became a necessity to guarantee a seamless and harmonious appearance.

Undertaking an extension to an operational hospital posed significant challenges for KSC, with a focus on safety considerations for both the construction site and its surroundings. Simultaneously, the team grappled with the constraints of an extremely small job site that offered limited storage capacity. In response to these challenges, offsite prefabrication was as a critical component of the project plan. This approach aimed to deliver a high-quality, efficient project while minimizing disruptions on the busy hospital campus. The logistical challenge of the limited space on the active job site necessitated strategic planning for material deliveries from Dallas to San Antonio on a weekly basis.

Given the small footprint, KSC had to store and fabricate the majority of the pieces off-site. Despite this constraint, our team's expertise in off-site fabrication of large-scale products proved invaluable. We seamlessly delivered finished panels to the worksite on an as-needed basis, allowing for easy coordination with other trade partners. This strategic integration of offsite fabrication not only overcame spatial limitations but also contributed to the overall efficiency of the project.

The new podium, positioned adjacent to the existing Sky Tower but oriented perpendicualarly, creates a dynamic visual contrast. The 10-story tower, slightly apart from the Sky Tower and set askew on its 4-story podium, maximizes scenic views and establishes a clear identity within the campus. The overall result is a 360-degree uniform and symmetrical look, enhancing the coherence of the entire project. Innovative construction techniques, including the unique ACM fin on the north elevation, add sophistication and facilitate a seamless transition from exterior to interior. This careful balance makes the project a standout addition to the campus landscape.

KSC's work on this project was selected as both a 2024 TEXO Distinguished Building Award winner and a 2024 AGC-TBB Outstanding Construction Award winner in the specialty contractor – exterior categories.

LOCATION

San Antonio, TX

BUILDING OWNER

University Health System

CONTRACTOR

JE Dunn

MANUFACTURER

KSC, Inc

DATE COMPLETED

2023