White Paper

Service Life Assessment of Low-Slope Metal Roof Systems

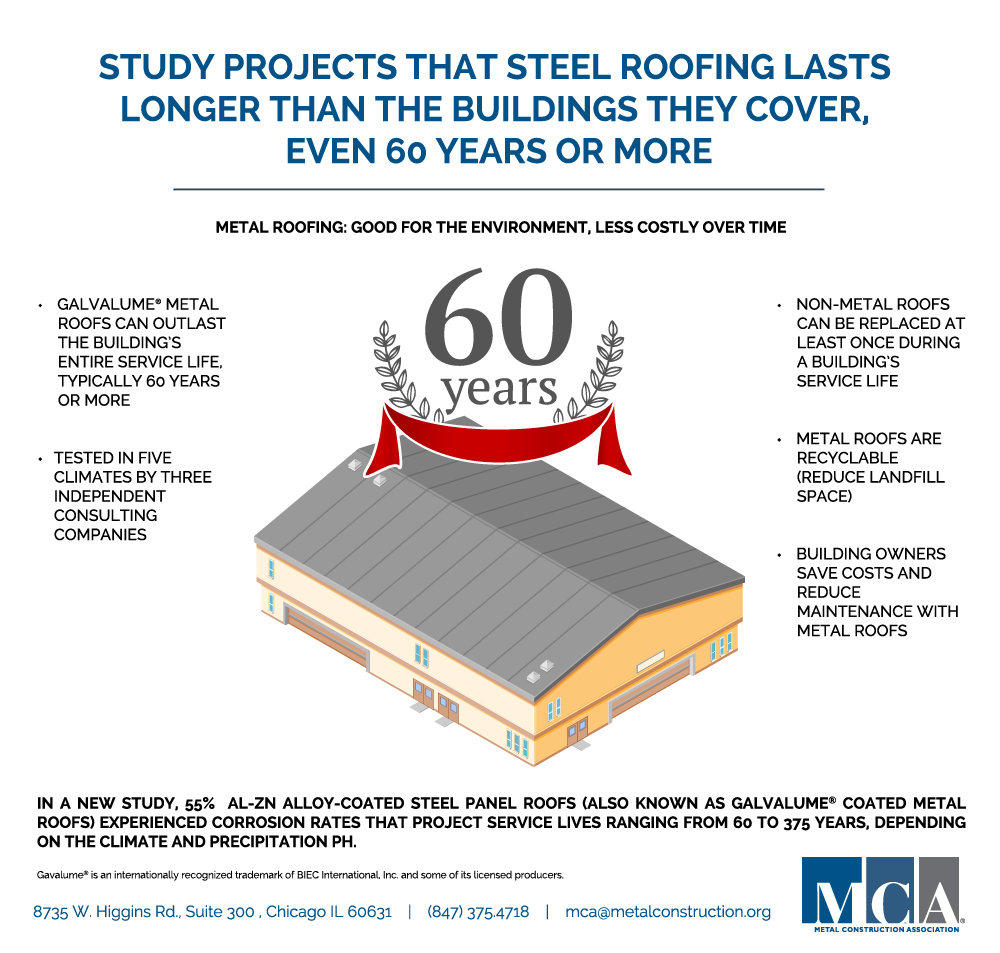

This report documents and summarizes the work conducted to determine with reasonable certainty the roof service life that can be expected of a “like-in-kind”, low-slope 55% Al-Zn alloy-coated steel Standing Seam Roof (SSR) system when installed today in a like environment using best practices. It incorporates the results of multiple field inspections, independent laboratory analyses of metallic corrosion of roof panels, components and sealants, and includes assessment of all integral ancillary components that impact the end of roof service life.

Based upon the field inspections of 14 low-slope, unpainted 55% Al-Zn alloy-coated steel standing seam roofs with up to 35 years of service across the United States, the following conclusions can be drawn concerning roof system service life:

• Butyl sealant life will be the deciding factor in establishing end-of-life for these roof systems. Butyl sealant has shown no significant deterioration in cohesive tensile strength or cone penetration values after up to 35 years of performance at laps and joints. Even in cases where some degree of de-polymerization was noted on some 26- to 35-year-old roofs, actual sealant performance was judged to be entirely adequate and without issue. Accordingly, sealant service life is conservatively projected at 60 years.

• 55% Al-Zn alloy-coated steel panels have weathered uniformly with corrosion rates that conservatively project flat panel service lives ranging from 60 to 375 years for an AZ55 coating, depending on the local precipitation pH. In all but the worst case (site #6), coating life is 79 years or more. For sheared edges and panel profile bends, the absence of significant red rust after up to 35 years indicates exceptional corrosion resistance in areas susceptible to exhibiting the first signs of corrosion.

• On many of the sites, ancillary roof components have begun to rust and exhibit inferior service lives that could negatively impact the service life of panels with which they are in contact. Thus, these components will require remediation. In most cases these corrosive components are not consistent with current best practice.

• The cost of projected remediation or replacement of these ancillary components was shown to represent significantly less than 20% of a total roof replacement cost, the value deemed to be excessive and, by which, would have constituted end of service life for the roof system. Therefore, ancillary service lives do not dictate roof service life, which is more directly a function of the butyl sealant at laps and joints

The 300 series stainless steel fasteners, cinch plates and other related hardware are ageing well, showing little signs of corrosion and no adverse effects on the 55% Al-Zn alloy coating. These metal components are expected to have a life consistent with or exceeding that of the metal panels. The same is true of integral aluminum components and ancillaries. Hence, these materials demonstrated excellent compatibility with 55% Al-Zn alloy-coated sheet. The 400 series stainless steel fasteners are showing varying degrees of corrosion, depending upon site location (atmospheric corrosivity), and will require replacement prior to end of roof service life.

• The expected service life of a similar roof constructed today in a wide range of environments using best practices can be expected to be in excess of 60 years, a value that equals the assumed building service life as described in LEED, version 4. This estimate is based upon the projected sealant service life, which has been conservatively projected due to a lack of measurable ageing and degradation of sealant.

• Although a 55% Al-Zn alloy-coated SSR system is relatively maintenance-free, a roof inspection program should be conducted on a regular basis to detect and eliminate problems before they lead to localized, premature corrosion that could decrease the service lives reported in this study. On sites where deciduous leaves, pine straw, dirt and other fallout accumulate, periodic cleaning, at least bi- annually, is prudent. In wet climates, where roofs are prone to algae growth, cleaning at even 5-year intervals will help maximize the service life of the roof.