With Zinc Comes Gold

355 11th Street, San Francisco, CA

View Case Studies

When does zinc become gold? When a perforated and corrugated zinc envelope helps transform an industrial, turn-of-the-century building—once a bottle-storage facility for an adjacent brewery— into a prime example of innovative green design and construction. Today, 355 11th Street in San Francisco is one of the city’s first Gold LEED®-NC buildings and winner of numerous presti- gious awards for both design and green building.

The project was developed and constructed by Matarozzi/Pelsinger Builders, a general contractor specializing in green building that now occupies the building’s second floor. Design professionals lease the third floor, and a restaurant, a LEED-NC Platinum candidate, will occupy the building’s first floor and exterior courtyard.

Renovation Challenges

Zinc was selected for the building envelope because it’s affordable, workable, and durable, according to Peter Kellner, senior project manager for Matarozzi/Pelsinger Builders, San Francisco. “It had the right look and matched the building’s original tin panel,” he says. “It also doesn’t require painting, ever—a huge benefit.”

Shane Curnyn, project architect for Aidlin Darling Design, San Francisco, further notes that zinc was chosen for its longevity, low maintenance, and rich, natural finish. However, he added, converting this historic building to a multi-tenant work- space meant dealing with several constraints imposed on the new building envelope.

First, ample light and air were required for the new office spaces. “Because of the building’s historic status, the city’s plan- ning department placed strict limitations on the introduction of new fenestration,” he said. “Moreover, the building’s original corrugated siding was required to be replaced ‘in-kind’ to preserve the industrial character of the building.”

The solution was to replace the old corrugated, galvanized, mild steel panels with perforat- ed zinc ones that were set in front of, rather than flush to, the windows. The breathable envelope allows light and air to pass through the new, but hidden, operable windows.

To add texture and create dif- ferent levels of transparency, the design team varied the size of the perforations and used solid panels where there are no windows. The panels range from 4% to 40% transparent.

“The perforated panels reduce solar loads and enable cross- ventilation of the interior,” Curnyn explained, adding that the double- skin façade also maintains the character of the original building.

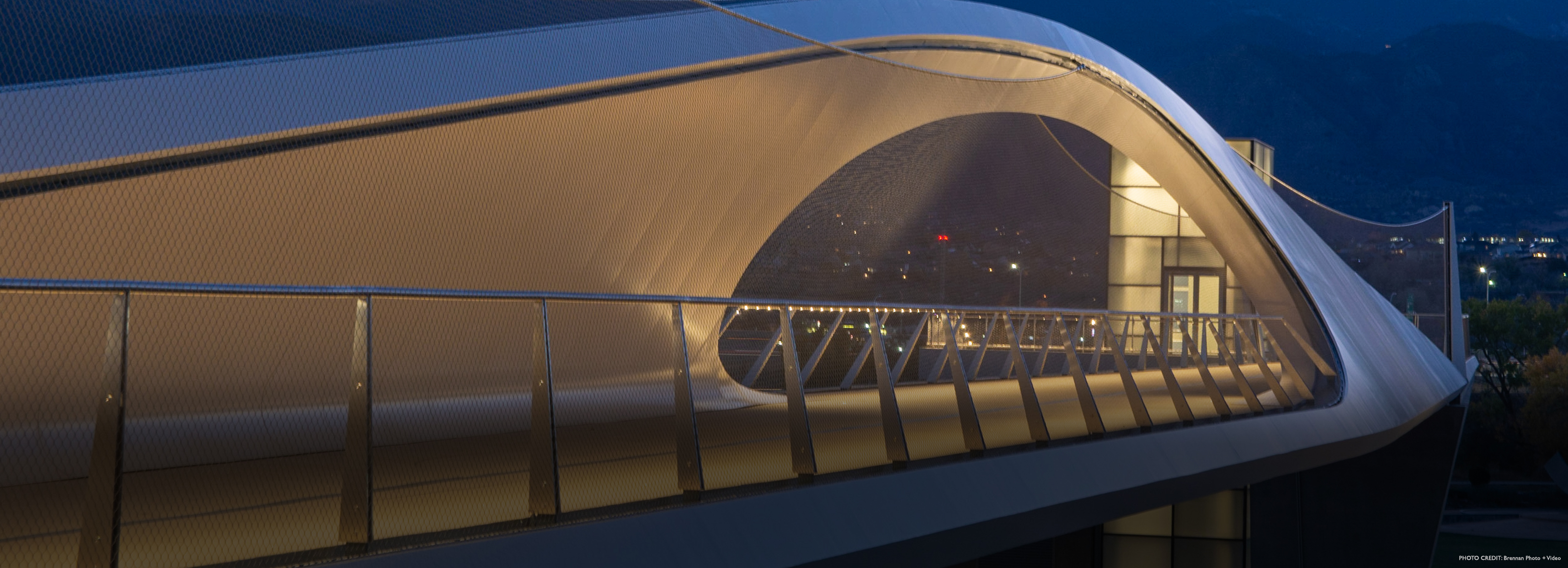

The pattern of the perforations was considered a design oppor- tunity. “Customized CNC milling created a seamless, building-scale gradient across the entire façade,” Curnyn said. “As a result, the smooth gradient reveals both the reflections of the glass during the day and the glow of the interior at night.”

Four corrugated panels were stacked and cut simultaneously without increasing milling time or cost. The result is 12 unique panel types that repeat four times each.

The Zinc Advantage

Officials at Aidlin Darling Design stress that the zinc envelope helps

- maintain a monolithic façade by disguising windows behind the diaphanous screen

- reduce solar-heat gain by pro- viding shade for the southwest windows

- enable cross-ventilation and passive cooling

- hide unsightly views of adjacent buildings

- reveal the historic structure. In the evening hours, the skin reveals the modern façade, as well as the historic post-and- beam interior structure.

Despite this, and the many accolades and awards bestowed on the building, Kellner sums up the collective view of the zinc envelope in this way: “People think it’s really cool.” There’s no disputing that fact.

Building

355 11th Street

Location

San Francisco, CA

Size

14,000 square foot, three-story building

Owner

Matarozzi/Pelsinger Builders

Original construction

1912

Original use

Bottling Plant & Warehouse

Date of renovation

2008

Completed

September 2008

Architect/Interior dDsigner

Aidlin Darling Design

Project Cost

Approximately $3.25 million

Metal Siding

Custom-Milled Corrugated / Perforated Zinc