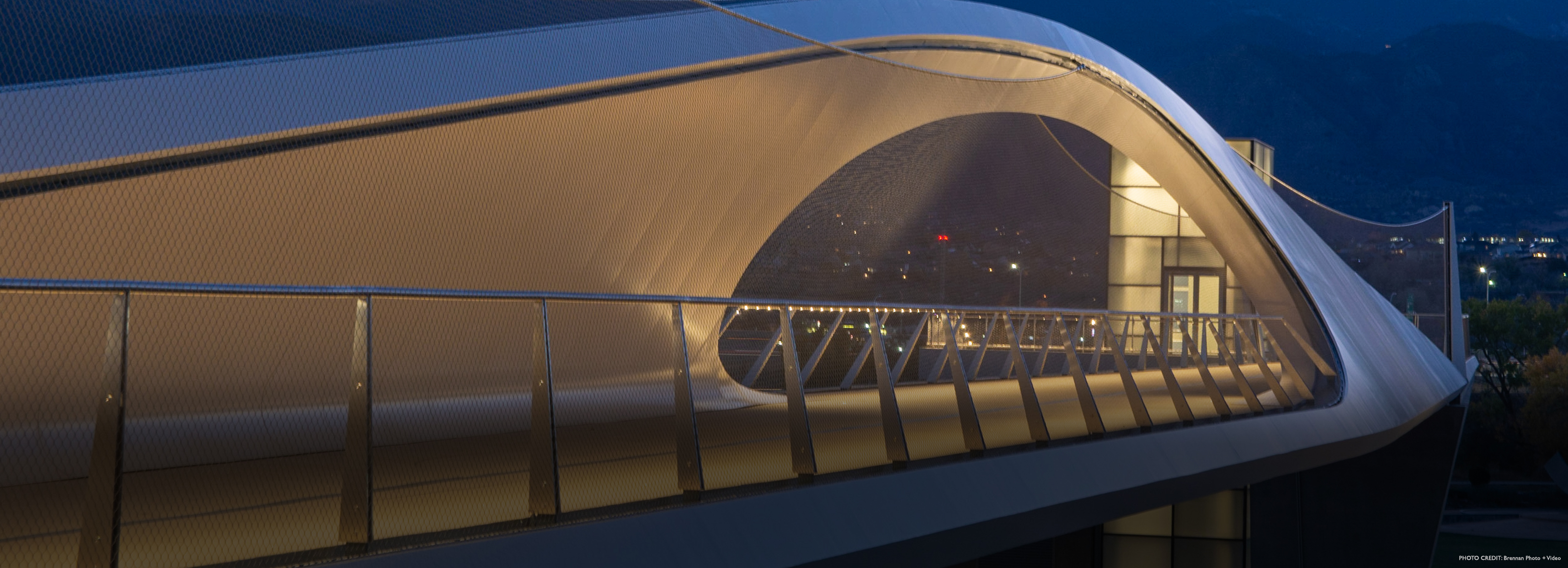

Magnolia Parkway Storage

View Case Studies

ABOUT THE PROJECT

Magnolia Parkway Storage is a mixed-use facility made up of approximately 50,000 square feet of climate- and non-climate-controlled self-storage space and about 5,000 sq. ft. of office and warehouse space. Jordan General Contractors, Inc.—a design-build, turn-key commercial general contractor—led the project from design and budgeting through construction. Jordan selected MBCI metal panels and components to achieve a modern design with varying textures within a reasonable budget, citing the“value, durability, product longevity and strength” of MBCI products.

As customers and architects move away from the standard “box” metal building design, custom solutions from contractors and building material suppliers are required. This growing trend is also attractive to local jurisdictions and municipalities that now require specific “architectural” exterior finishes, sometimes requiring masonry and glazing finishes. Mixing these with metal exterior sheathing can be challenging when trying to create an “aesthetically pleasing look”. MBCI’s wide range of products and panel profiles—which are available in a wide variety of colors and can be installed both vertically and horizontally—can be integrated with almost any design to create the look customer desires.

ABOUT THE PRODUCTS

To develop a modern, architectural aesthetic in a cost-efficient manner, a combination of MBCI products in varying colors was selected:

• Roof System: MBCI’s 24-gauge Ultra-Dek panels were selected for their versatility, longevity and unmatched aesthetic. Covered by MBCI’s 40-year finish warranty, the panels will be maintenance-free for years to come.

• Hallway Panels and Trim: PBD exposed-fastened panels featuring symmetrical ribs for a uniform aesthetic

• Partition Panels: PBU exposed-fastened panels provided the versatility required for a partition application

• Exterior Sheeting: PBR and PBU were selected for their durability and versatility, which allows for various horizontal and vertical architectural designs while maintaining their cost-efficiency.

Custom broke flat (door mullion) trim was also incorporated into the project.

WHY MBCI?

No amount of planning and preparation during the design phase can guarantee that construction will go smoothly. Unexpected challenges and changes are almost always part of any build. The team at Jordan chose to partner with MBCI on this project not only because of the unmatched product quality, but because the MBCI support team is “always responsive and provides immediate support and problem-solving solutions” critical to project success.

In addition, Jordan’s experience using MBCI products—particularly roof and hallway systems—gave them the confidence to incorporate them as early as the project design phase to ensure the build was properly planned. This helped streamline the creation of bills of material (BOMs) as well as the installation process to reduce project delays and cost over-runs.

For more information on MBCI’s metal building solutions, please contact a member of our sales team, or register for an MBCI online ordering account to view all product details and pricing anytime, anywhere.

LOCATION

18015 Farm to Market Rd 1488, Magnolia, TX, USA

CONTRACTOR

Jordan General Contractors, Inc.

MANUFACTURER

MBCI