Scientific Method

Metal lends a sense of scale to a biotech logistics center.

View Case Studies

Any company with an eye to the future has to plan for growth. That applies to staffing and internal infrastructure, and it also applies to the architectural design of a company’s offices and facilities.

Promega Corporation is a global leader in applied biochemistry and molecular biology. The Madison, Wisconsin–based company boasts a portfolio of more than 3,500 products in the fields of genomics, protein analysis and expression, cellular analysis, drug discovery, and genetic identity.

As Promega continues to grow and expand around the globe, so must its facilities in the Madison suburb of Fitchburg. A new processing center was needed to plot the movements of Promega’s products from the campus. It would come to be known as the Kepler Center, named after Johannes Kepler, who plotted the movements of the planets.

Built to Grow

As a growing company, Promega wanted this new facility to be able to expand and double in size, explains Steve Wellenstein, project architect with Milwaukee, Wisconsin–based design firm Uihlein/Wilson. “We had to design it as a full building and then pare it down in size so it was the correct size for right now.”

From the beginning, the architect was attracted to metal panels for the project. Metal played well into the concept of modular expansion the owner was looking for.

“One of our thoughts was that we might be able to remove the metal panels and reuse them on the new elevation when it moves,” Wellenstein says. “We also had to do this to a budget. We had looked at precast concrete and brick, but the cost of brick and precast with the detail we wanted was too expensive for this type of building, so we quickly went to metal panels.”

Once the decision was made to use metal panels, the design team knew just where to turn.

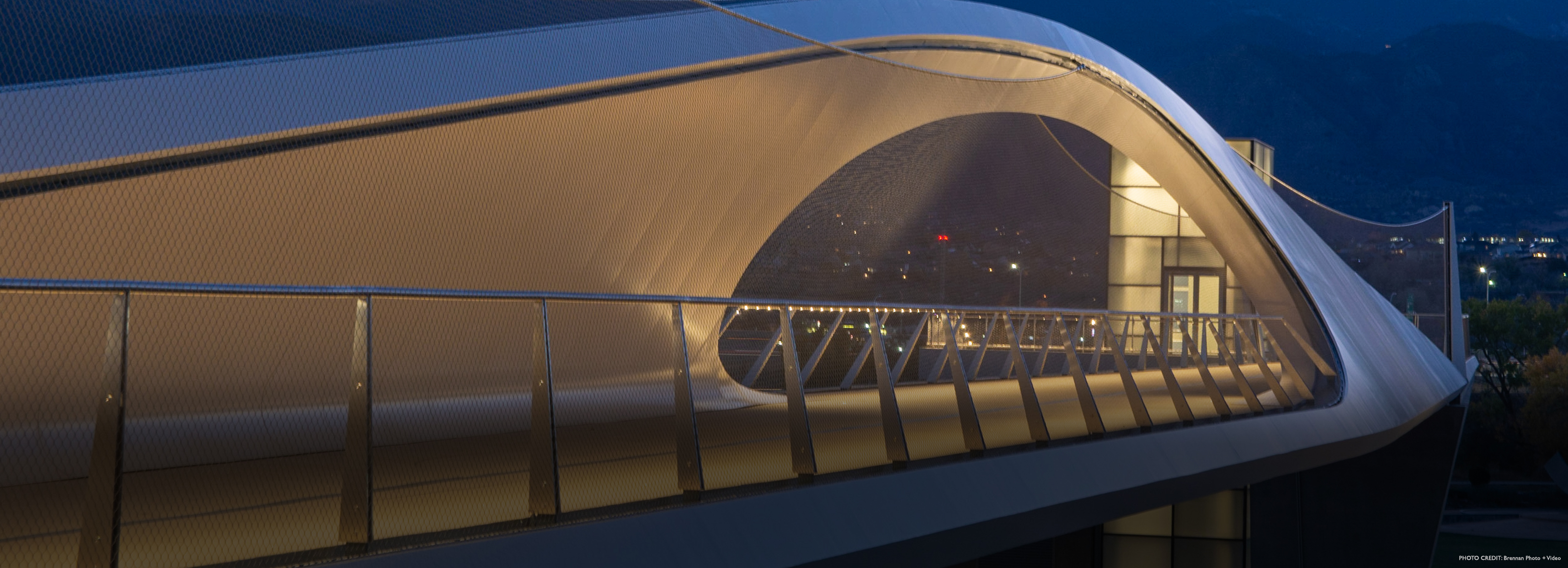

“CENTRIA is always our go-to for metal panels and metal siding. They have good representation in the area and always do a good job,” Wellenstein says. “They helped us with the insulated metal panels we have on the front office block because the design was curved. We originally started out thinking about doing that a little differently, but they made suggestions based on what we were trying to achieve and we went that route. It was easy to accommodate, and CENTRIA was very helpful.”

Size and Scale

At 126,000 square feet and 44 feet high, the Kepler Center is massive, but there was a desire to try to downplay its size visually so as not to overwhelm. “Because it is such a big building, the biggest problem we had was dealing with the scale of it,” Wellenstein says. “If it was just precast panels, it would look monolithic. What we were able to do was use large bricks on the exterior. The bricks are almost the size of concrete blocks, with more character and depth than concrete block.”

The bricks were used in concert with large windows and multiple types of CENTRIA metal panels to create a textured detail that was large in scale.

“We ran the [CENTRIA] Super-Rib panels horizontally to help bring down the height of the building and give the illusion of the building having movement across the site, rather than just extruded up,” Wellenstein explains. “The horizontal elements of the canopy and window pattern express this as well. Rather than an entry tacked onto a box, we layered the materials and elements to give the entire design better scale. With the Super-Rib panels, we got nice shadow lines. We also used Econolap panels. Without these, it would have just been one tone and we wouldn’t get shadow lines.”

Deploying this array of materials in a thoughtful way has the effect of tricking the senses and making the building appear more visually accessible. “Everything was deliberate, trying to make things appear different in terms of scale from the exterior,” Wellenstein says. “It makes the building feel smaller when you are at a distance from it, but people walk in and are struck by how large it is. It was interesting to play with that. One of our goals was to keep the building to a human scale without putting too much detail into it.”

Team Effort

The entire approach of this project was very team-oriented, with all players involved every step of the way. Uihlein/Wilson led a unique process that kept everyone on the same page throughout.

“We use a process called ‘design workshops’ with the owners,” Wellenstein says. “It’s not just progress meetings. These are actual meetings where the owners are there, and we are discussing specific options and going over the pros and cons of different materials. The team weighs in, but the owner has the ultimate vote.”

The team included the owner; the mechanical engineers; a site engineer; a civil engineer; a landscape architect; an architectural consultant; users of the building; Uihlein/Wilson; and Plain, Wisconsin–based Kraemer Brothers Construction, the contractor that worked closely with the design team and the owners from the very beginning. There were many advantages to having everyone at the table for regular updates as the project moved forward.

“For example, if we’re meeting and discussing using metal panels, Kraemer Brothers is there to let us know immediately if that is in the budget. Or if we suggest brick, they are there to let us know that is not in the budget,” Wellenstein says. “That’s why this is good, because we are all updated on what the costs are as we develop what the design is, rather than going through the whole process of design and having everyone be surprised by the costs at the end.”

The Kepler Center opened in spring of 2016. Promega is pleased with its new facility, and just over a year in, it’s already starting to fill up.

“The owners love it, and it’s good that we planned for things to be expanded,” Wellenstein says. “I think we had 50 minus-70 freezers in the facility at the beginning, and now there are 70. They are filling up the building and using it as planned. The company has been doing really well and growing, so that’s a good thing.”

LOCATION

Fitchburg, WI

CONTRACTOR

Kraemer Brothers LLC

MANUFACTURER

CENTRIA

BUDGET

n.a.

SIZE

126,332 square feet

DATE COMPLETED

October 2015