Church's Metal Roof Achieves Perfect Pitch

St. Aloysius Church, Jackson, NJ

View Case Studies

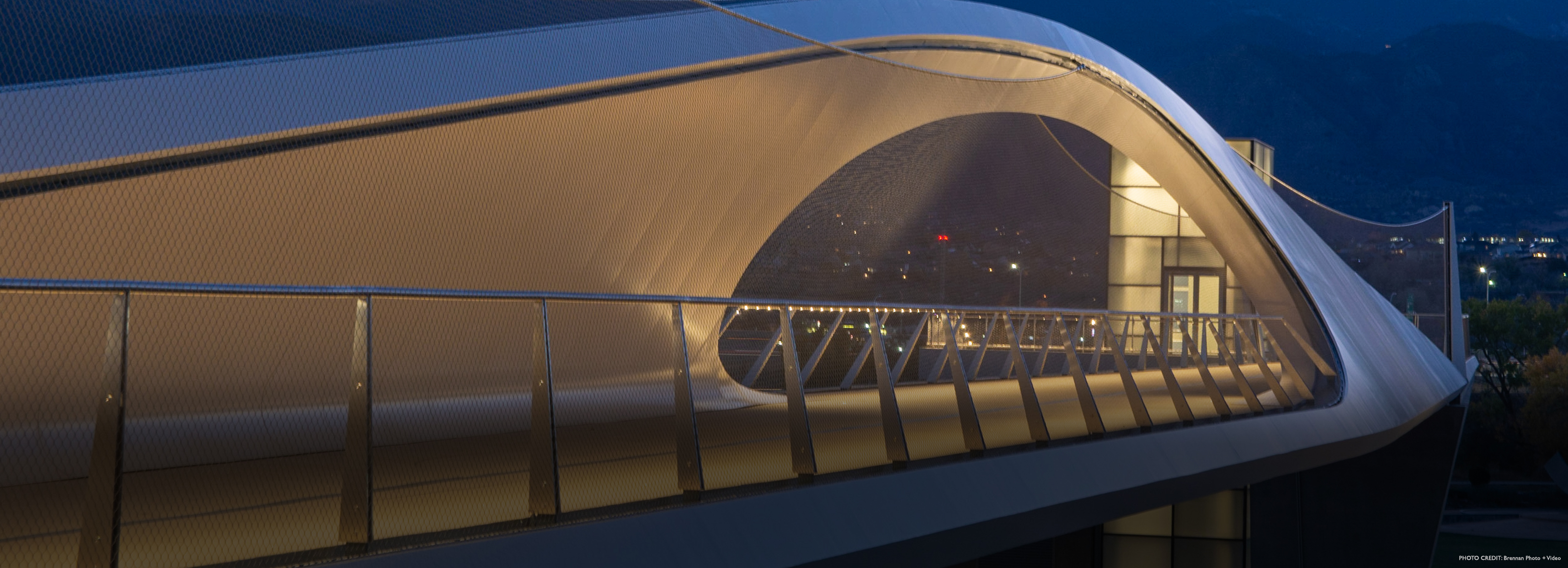

At first, the high-concept design of the new St. Aloysius Church and its prominent, eye-catching metal roof was greeted in its Jackson, NJ, community with some degree of skepticism. Phrases such as “the flying wimple,” “the flying nun,” and “spaceship” circled about town to describe the project.

Today, however, the hyperbolic paraboloid–shaped metal roof receives high praise and appreciation from within and well outside the community for its biblical-based “repitching the tent” design that warmly invites parishioners to gather inside its sloping confines for worship.

“The effect when you come into the church is that you feel as if the roof is coming down, embracing you, and focusing your attention on the altar,” said Reverend Scott Shaffer of St. Aloysius, who was charged with building the new Roman Catholic church in this quickly expanding community.

Outside, the metal roof’s design—its soaring lines, sky-gray color, and six massive anchoring piers—is thoughtfully rooted in Old Testament references to God’s presence in the Ark of the Covenant housed in a tent.

“We very much wanted the roof to look like a tent, and the computer-aided design allowed us to draw it fairly easily,” said Architect David McHenry, principal of Erdy McHenry Associates, Philadelphia, PA. “But finding a structure that could actually accomplish it was another task all together. A hyperbolic paraboloid is used primarily for inexpensive long-stand solutions—usually for college athletic facilities.”

“The curved shell of a roof is a wonderful thing. Once we had that, it was perfect,” McHenry added. “The challenge was finding a material that would provide the quality and long life-span appropriate for a church. A metal roof was able to follow the curves of the structure. By virtue of its shape, the roof gets very close to the ground in several instances [where it receives close scrutiny]. It was important that that material be of high quality, both visually and texturally."

For the roof material, the architect chose a 17-in., 24-gauge standing seam panel. There is more than 37,000 sq ft of gray galvalume metal covering the roof. Installing the standing-seam roof proved to be a challenge. Although the roof gives an impression of having curves, no curved material was used, and each panel had to be meticulously planned and installed. “We had to hand seam every single one of the battens,” said Brian Swarthout of Excel Contracting, Inc., Beachwood, NJ. “But once [we] got rolling on it and got a system, we got going pretty well. We actually separated into two crews, one doing insulation and the other doing the panels.”

Today, the stunning design of the roof and building remains a visual treat to parishioners and people driving by the structure, which is located at the forefront of a 16.6-acre site that houses several St. Aloysius facilities. “The design [is] of the meeting tent rising out of the ground,” said McHenry. “The six stone piers represent the pegs of the tent anchoring the roof structure, while the parabolic plywood sheathings allow the tent structure to soar.”

Moreover, he said, “The overall shape of the roof is something that certainly draws a lot of attention. Once we captured someone’s eye, we wanted to make sure it was of a quality material that was appropriate for that level of attention.” Metal hits that note beautifully.

ARCHITECT

Erdy McHenry Architecture, Philadelphia, PA

METAL INSTALLER

Excel Contracting, Inc., Beachwood, NJ

OWNER

Roman Catholic Diocese of Trenton, New Jersey

AWARDS

- Best Overall Architectural Design, McGraw-Hill New York Construction

- Best of 2009 Award (Northeast region)

- Best Worship Project of the Year, McGraw-Hill New York Construction

- Best of 2009 Award (Northeast region and National)

- 2009 Metal Construction Association’s President’s Award for Best Metal Roof

- 2009 Metal Roofing Design Award, Metal Architecture magazine

SUSTAINABLE ELEMENTS

- Radiant underfloor heating in the sanctuary

- Extended building overhangs to reduce cooling load

- Large earthen berms around the building perimeter to add additional insulation to the building

- Large infiltration basins and cisterns to capture and filter the storm water from the roof

- Bioswales in the parking lot to capture and pretreat some run off